Valves are made in a variety of types and sizes. As its basic function, a valve is simply a device that can be opened or closed to the flow of liquids of gasses. A kitchen faucet is a great example of a valve we use every day. In this article, we're going to discuss one type in particular, the ball valve.

A ball valve is a form of quarter-turn valve that uses a pivoting ball that has been drilled through to control flow. When the hole is in line with the flow direction, it allows fluids or gasses to pass through. Alternatively, when the ball is turned 90 degrees, the flow is stopped completely. In either case, the handle serves as a visual indicator of the valve’s status. If the handle is parallel to the valve, it's open. In contrast, if the handle is perpendicular, the valve is closed.

Ball valves are incredibly robust valves and great for applications where a simple on/off action is needed. They're durable and maintain their ability to perform consistently after many cycles. Additionally, they have excellent reliability and close securely even after long periods of disuse. Flow rate can also be controlled by partially opening or closing the valve to various degrees. These qualities make them an excellent choice for shutoff and control applications over gate and globe style valves. However, ball valves lack the finite control that these other valves offer for throttling applications.

Though it is an easy mistake to make, ball valves are not the same as the similarly named "ball-check valves". Ball-check valves are a type of one way valve that prevent undesired backflow.

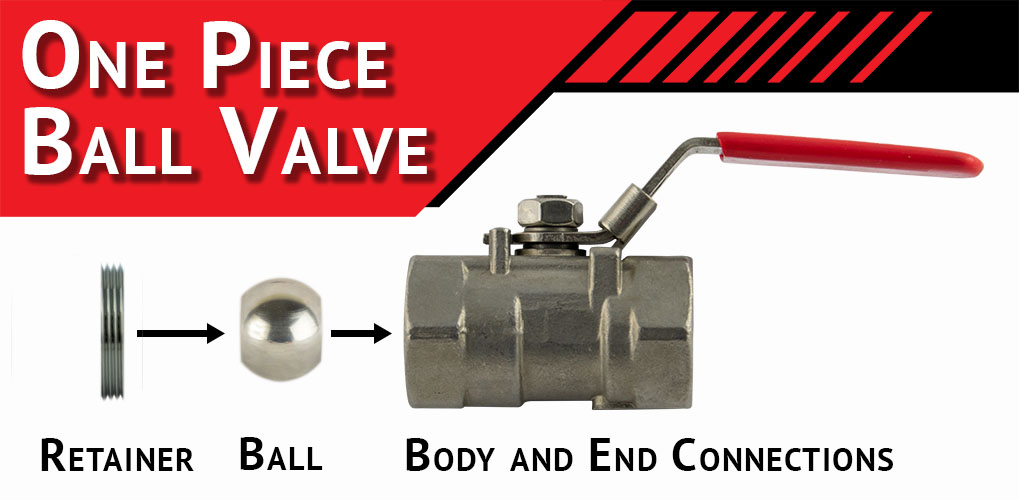

One-piece ball valves consist of a body and end connections formed from a single piece of material. Due to its makeup, the one-piece ball valve significantly reduces its chances for leakage. Because the seals and valve trim must be inserted through one of the end connections, this type of valve will always have a port size smaller than the inner diameter of the pipe to which it connects. This narrower port, often referred to as a reduced port, can cause pressure drop due to the restriction in flow. In addition, this valve assembly must be removed entirely from the piping system in order to be serviced. Because of the lower cost of the one-piece design, and the difficulty of valve maintenance, one-piece ball valves are typically replaced entirely rather than repaired.

Mako One-Piece Valves:

Two-piece ball valves consist of two separate pieces that are connected with a bolt or threaded assembly. Typically, one-piece includes the body and one end connection. Subsequently, the other piece secures the trim into the valve and includes the second end connection. This assembly type allows two-piece ball valves to have a port size that is equal to the connected pipes. When this is the case, they're referred to as full port valves. Since there is no pressure drop, flow rate can be much higher on full port valves. Additionally, two-piece valves can withstand pressures from both sides making them effective for bidirectional flow shutoff. Two-piece ball valves are usually also the most cost efficient full port valve on the market.

Mako Two-Piece Ball Valves:

Three-piece ball valves are separated into two end caps and one body. Unlike the other two types, the body of a three-piece valve can be removed separately from the end caps. This design means three-piece ball valves are much easier to clean and service when needed. Clearly, this makes them preferable in situations when ever frequent cleaning is required. These valves are widely used for sanitary applications in pharmaceutical and food/beverage industries. Three-piece ball valves are typically more expensive, but are proven valuable when considering their added functions that are essential for certain applications.

Superlok Three-Piece Ball Valves:

· SWB320

Ball valves come in many shapes, sizes, and materials. Furthermore, finding the right ball valve for your specific application can be tedious and time consuming. If you have questions or would like to request more information on a specific product, contact Mako below. We're always here to answer questions and help you find the right valve for the job at hand!

Check out our blog for the latest updates and how-to's from Mako Products!